全国服务热线

13503801616

全国服务热线

13503801616

新闻资讯

News

堵转1小时-24小时的电机设计理念 长期堵转力矩电机如何闭环控制

闭环式扭力控制在力矩电机应用是通过力矩电机加装编码器来反馈信号完成的。通过接收信号与控制器预先设定的张力值相平衡,计算出控制信号,自动控制动作单元则使实际张力值与预设张力值相等,以达到张力稳定目的。它是目前较力矩电机的张力控制方法简单易行、成本低。用变频器驱动变频电机做张力控制是变频电机加编码器采集脉冲信号完成的。但工艺复杂成本高。

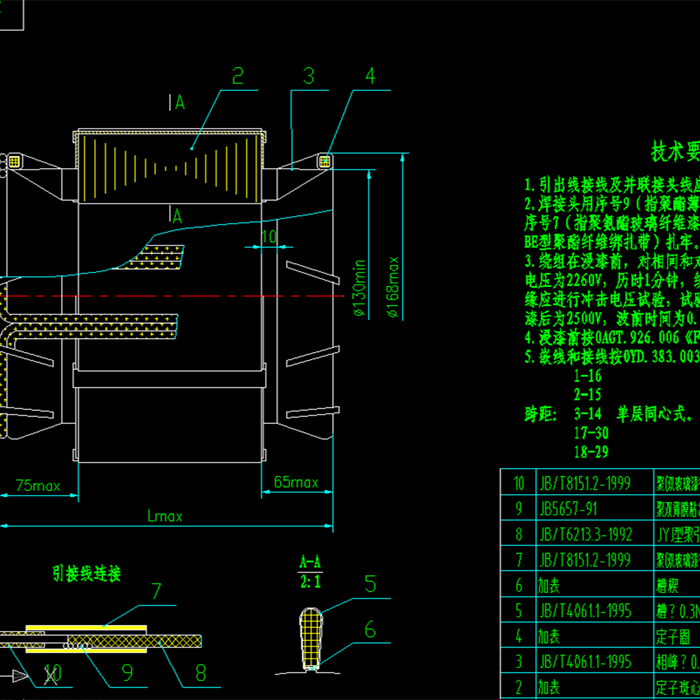

三相长期堵转异步电动机 电磁设计单

* TYPE:Y-132S-6 B25:15900.00 P10: 1.86 Insulate: *

* Power: 3.00 (kw) P: 6. U:220. f: 50. Name: Date: *

............................................................................

* Q1=36. D1 =210.0 D2=147.3 STATOR ROTOR *

* Q2=42. Di1=148.0 g = .35 U1: 220. Ty= 72.57 *

* L = 85.0 Leff= 85.7 A : 1. Fd1= 21.64 *

* L1= 80.8 L2= 80.8 zf: 516.0 D = 15.00 *

* b01= 3.50 b02= 1.00 z : 43. *

* bs1= 6.3 br1= 4.90 Czn: 1. *

* Rs = 4.10 br2= 2.00 N1*d1: 1.*1.18 *

* hs1= .81 br3= .00 N2*d2: 0.* .00 *

* hs2=10.99 br4= .00 S : 1.09 *

* Hs0= .8 hr0= .5 Y : 5.00 *

* bt1= 6.9 hr1= 1.1 Lz: 202.1 *

* bt2= 5.8 hr2=19.9 Gcu: 3.2 1.1 *

* bt3= .0 hr3= .0 R1: 2.0691 1.2781 *

* t1 =12.92 t2 =11.02 J : 6.10 2.66 / 2.03 *

* Zs1=30.00 Zs2= 30.0 Sk: 12.92 *

* hc1= 15.7 hc2= 28.2 Se: 86.51 *

* Zc= 1. Sf: .7891 *

............................................................................

* kd kp kdp zfk kc *

* stator: .9659 1.0000 .9659 498.4 1.2949 im= .7481 *

* rotor: 1.0413 ir= 1.168 *

* Tp = 77.49 Fs =1.4715 Ft =1.2500 1.3483 ix= .889 *

* Ke0= .9506 Ke1= .8984 Ft0=1.3489 i1=1.4676 6.67 *

* Fa= 354936.30 *

............................................................................

* mm*mm B L AT/cm AT i2=1.183 191.5 *

* st: 3344.2 15618. 13.2 18.92 25.18 pcu1= .0921 276.2 *

* sc: 1265.1 14028. 50.9 5.46 11.29 pcu2= .0370 110.9 *

* rt: 3293.2 15860. 21.0 23.67 46.34 pfe= .0247 74.2 *

* .0 0. .0 .00 Ps= .0060 18.0 *

* rc: 2273.1 7807. 19.9 1.40 1.95 pfw= .0116 34.7 *

* g0: 6641.1 7864. .47 296.91 pg= .1714 514.1 *

* Ikw= 4.55 a c1=.406 c2=.700 AT= 381.68 p1=1.1678 3503.5 *

* Im = 3.40 a *

............................................................................

* Eff Pf Tm Tst Ist AJ Sn *

* .8535 .7958 3.15 2.46 6.42 1354.8 .0353 *

* JB: .100%0 .7600 2.10 2.10 6.50 .2572 *

............................................................................

* B0 Cm**3 w/cm**3 p Si Wi Hw *

* st: 16009.6 302.0 .037 10.58 .30 .08 2.0 *

* sc: 14757.6 772.4 .031 23.88 *

* Gfe= 27.8(Kg) PPfe= 74.2 I10= 3.81 a P10= 200.4 S0= .0006 *

............................................................................

* A1= 222.09 H1= .0265 LB= 85.0 SB= 71.9 *

* Cx=.02892 H2= .0169 Dr= 121.5 Sr= 210. *

* Ku1=1.0000 Spu1= .3935 Ku2=1.0 Spu2= .500 rb= .0196 Rb= .947 *

* KL1=1.0000 SpL1= .7390 KL2=1.0 SpL2= 1.655 re= .0068 Re= .331 *

* Sp1=1.1325 Sp2= 2.155 r2= .0264 R2= 1.28 *

............................................................................

* Xs1= .6019 cx Xs1s= .5929 cx Kcc= 1.42 *

* Xd1= 1.1355 cx Xd1s= .4120 cx XXo= .92 kax= .000 *

* Xe1= .2928 cx Xe1= .2928 cx rro= 1.19 kar= .000 *

* X1= .0587 X1s= .0375 ATst= 2289. *

* Xs2= .9162 cx Xs2s= .8271 cx BLg = 40871. Kzg = .363 *

* Xd2= .6750 cx Xd2s= .2449 cx Bls1= 4542. Kzs1= .931 *

* Xe2= .1789 cx Xe2= .1789 cx Bls2= 12713. Kzs2= .833 *

* Xsk= .4637 cx Xsks= .1682 cx Cs1= .26 *

* X2= .0646 X2s= .0410 Cs2= .20 *

* X= .1233 Xst= .0781 dspu1= .0171 *

* r1= .0427 r2s= .0302 dspu2= .0834 *

* R1= 2.0691 rst= .0719 spl2s= 1.5291 *

* r2= .0264 zst= .1061 sp1s= 1.1154 *

* sp2s= 1.9457 *

----------------------------------------------------------------------------

返回顶部